Health & Safety Over The Last 50 Years.

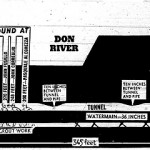

Fifty-two years ago, a workplace tragedy that killed five immigrant workers became the catalyst for reforms in occupational health and safety.

The Hogg’s Hollow disaster of March 1960 sparked public outcry that caused the Ontario government to modernize safety regulations, leading to the enactment of the Industrial Safety Act in 1964. In the same decade, the federal government passed the Canada Labour (Safety) Code, setting out laws and regulations for safety of workers in the federal jurisdiction.

Around the same time as these major developments, Canadian Occupational Safety magazine was born. The very first issue of COS magazine hit the streets in March 1963, and was published by Cash Crop Farming, a small publishing firm in Delhi, Ont.

A lot has happened since then, and in honour of the 50th anniversary of the magazine the Canadian OHS community has come to rely on for their regular dose of health and safety information, we’re looking back at some of the most unforgettable events in safety history in the last half-century.

1964: Safety defined

The Industrial Safest Act is enacted replacing the Factory, Shop and Office Building Act. Safety is defined as “freedom from injury to the body or freedom from damage to health.” Employers were required to take such precautions as are reasonable to ensure worker safety.

1968: Canada Labour (Safety) Code takes effect

The code prescribes laws and regulations pertaining to occupational health and safety of workers in the federal jurisdiction.

1972: Saskatchewan leads

In passing its own Occupational Health and Safety Act, Saskatchewan institutes the concept of internal responsibility system by making health and safety a joint responsibility of employer and employees and requiring the establishment of joint health and safety committees. It enshrines three fundamental rights of workers: the right to know about the hazards in the workplace; the right to participate in health and safety discussions at work; and the right to refuse unsafe work.

1974: Striking miners

Uranium miners in Eliot Lake, Ont. stage protests unsafe working conditions and high incidence of lung caner and silicosis. In response, the Ontario labour ministry establishes a Royal Commission led by Dr. James Ham, to study and make recommendations to improve health and safety of mine workers.

1976: Beyond the mines

The Royal Commission publishes the Ham Report with over 100 recommendations. The occupational health and safety division is formed with four branches: mines safety, construction safety, industrial safety and occupational health. The Board of Canadian Registered Safety Professionals is formed as a certification body for safety practitioners.

1978: Ontario responds

The Ontario Health and Safety Act passes, incorporating the internal responsibility system and recommendations from the Ham Report.

1978: CCOHS is born

The Canadian Centre for Occupational Health and Safety (CCOHS) is established, providing health and safety information, training and education.

1985: Remembering the fallen

Canada Labour Congress declares April 28 as Day of Mourning, an annual day of remembering workers who are killed on the job.

1986: JHSC goes national

Canada Labour Code requires joint health and safety committees for every organization.

1988: WHMIS established

Workplace Hazardous Materials Information System (WHMIS) is established and requires educating workers about chemicals in the workplace and how to protect themselves from the hazardous materials.

1992: Westray tragedy

Explosion at Westray coal mine in Pictou County, Nova Scotia, kills 26 miners. An inquiry follows the tragic incident and finds negligence and abuse on the part of mine owners and government inspectors. Criminal charges are filed against Westray owner Curragh, Inc. and four of its managers. Ministry of Labour officials, including the minister, are dismissed and replaced.

1997: NAOSH Week is born

The first North American Occupational Safety and Health Week is celebrated.

1998: WSIB is born

New Conservative government disbands Ontario’s Workplace Health and Safety Agency, revamps the workers’ compensation system and creates the Workplace Safety and Insurance Board (WSIB).

1999: Young workers

A series of workplace fatalities involving young workers result in the establishment of the Young Worker Awareness Program, spearheaded by the Industrial Accident Prevention Association and Workers’ Health and Safety Centre.

2001: 9/11

Terrorists hijack two passenger planes and crash them into the north and south towers of the World Trade Centre in New York City. Minutes later, another hijacked plane crashes into the Pentagon, and another on the ground in Pennsylvania. More than 3,000 people are killed in these terrorist attacks, including firefighters, police officers and other emergency responders. The event changes the world’s view on safety and security.

2004: Criminal liability

Bill C-45, a provision amending the Criminal Code, passes into law. The bill imposes criminal liability for occupational health and safety violations resulting in injury or death. It allows for criminal prosecution of organizations, including corporations, their representatives and those who have authority to direct the work of others. Bill C-45 is also known as the Westray Bill, after the Westray mine explosion of 1992.

2008: Four years later…

Quebec firm Transpave Inc. becomes first company to be convicted of criminal negligence under Bill C-45 following the death of a young worker. Transpave ends up with a $100,000-fine. It would be three years until Canada sees another Bill C-45 conviction.

2009: Workplace violence

Ontario passes Bill 168, a legislation amending the Occupational Health and Safety Act to include provisions for the prevention of workplace violence and harassment. Ontario joins other provinces, including British Columbia, Alberta, Manitoba, Saskatchewan, Quebec, Nova Scotia and Prince Edward Island, in addressing workplace violence and/or harassment through regulations.

2010: Confined space

Canadian Standards Association releases the first national standard on the management of work in confined space. CSA Z1006 is a voluntary standard that defines best practices for confined space work, and was developed with input from industry sectors such as energy and mining.

2010: Tony Dean reports

The Ontario health and safety review panel, headed by University of Toronto professor Tony Dean, releases its recommendations to improve the province’s health and safety prevention and enforcement system. Included in the recommendations are: the appointment of the first-ever Ontario chief prevention officer; the creation of a multisector Prevention Council; and the transfer of prevention functions from the WSIB to the Ministry of Labour.

2011: Canada’s Safest Employers

Canada’s Safest Employers Award honours outstanding companies that are making a difference in promoting the health and safety of their workers. Five companies emerged as the inaugural winners, earning the honour of being Canada’s Safest Employers.

2012: Canadian Occupational Safety turns 50!

Celebrating 50 years as Canada’s premier source of information for the health and safety community, COS magazine continues to find better ways to engage health and safety professionals, providing relevant information in print, online and in person.

Written by Mari-Len De Guzman is the editor of Canadian Occupational Safety magazine and www.cos-mag.com.

First Response’s Comments:

I find it fascinating to read about the evolution of Health & Safety over the last 50 years and how it has gone from virtually nothing, to sometimes being completely ‘hobbling’ for employers in some instances. In my experience, many employers are very pro active when it comes to H & S, however there are still many for whom Health & Safety is very challenging. Of course, no one wants an employee to get injured on the job, but the line between hand holding and due diligence is sometimes very gray and not as clearly defined as it needs to be. Many times, I have listened to workers relate their experience of trying to work safely whilst dealing with job deadlines. For some companies, abiding by the Health & Safety laws is so cost prohibitive that it takes them out of the playing field when bidding on a job. It is all well having laws that tell us how to work safely, but actually implementing those laws can often be very difficult and sometimes very impractical. I would love to hear your comments on Health & Safety in the workplace and how it effects you….

Did you know that May Is Hepatitis Awareness Month?

Did you know that May Is Hepatitis Awareness Month?